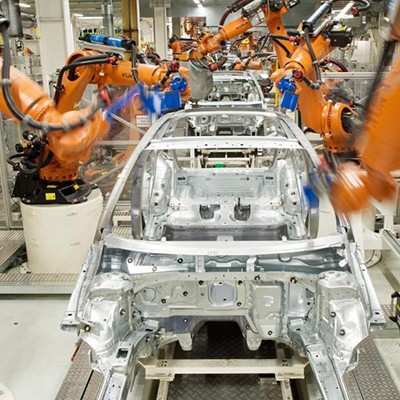

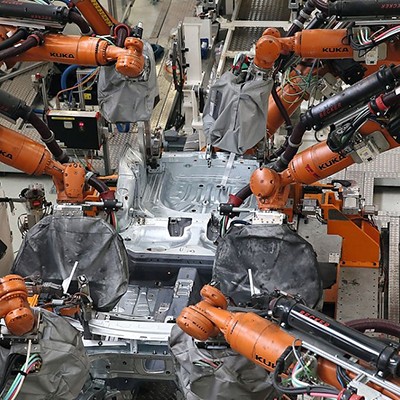

√ Prelube √ Forming √ Anticorrosive

Product information

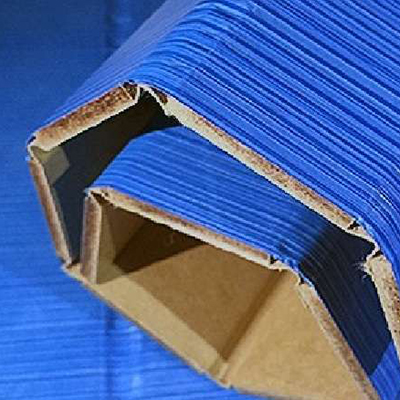

WEDOLIT N 22-3 is a thixotropic, water insoluble, deep-drawing agent for cold forming of uncoated carbon steels, zinc- and zinc/nickel-coated sheets, aluminized sheets, aluminium and aluminium alloys. Can be applied by spraying or by hand with a brush or by means of rollers.

Fulfils the requirements of all German automotive manufacturers according to VDA 230-213 and VW-A001, and has been approved by all VDA members.

Properties

· Before application, a heating of the oil to approximately 40 - 50°C is possible without loss of the thixotropic effect after cooling

· In any case, a filtration over a fine-meshed filter (< 50 μm) has to be avoided, due to the related loss of the thixotropic thickener

· An ageing stable film is formed after drawing

· Acts at the same time as a corrosion protection agent

· Re-preservation of the drawn sheets is not necessary

· Can be removed with organic solvents or water soluble, mild alkaline industrial cleaning agents, even after long storage periods

· After degreasing, phosphating treatment can be carried out without problems

Technical data

| Parameter: | Value: | According to: |

| Appearance: | beige, brow | visual |

| Density at 15℃: | 0.9 g/cm3 | ASTM D 7042 |

| Viscosity at 40℃: | approx. 80-120 mm2/s | ASTM D 7042 |

| Flash point: | > 190 ℃ | DIN EN ISO 2592 |

| Corrosion protection: | fulfilled | VW-52.01 / VDA 230.213 |

| Degreasing: | fulfilled | VW-52.01 / VDA 230.201 |

| Run-off behaviour: | fulfilled | VDA 230.213 |

| Kesternich Test: | 20 Runden | DIN EN ISO 6270-2 AHT |

Information

Storage must be frost-free between 5-40℃.The minimum durability is 24 months in an original sealed package.

All provided data can vary within conventional technical tolerances, without affecting the product functionality. In regard to the high diversity of the possible application parameters, all information provided under exclusion of any commitment and liability. More safety and environment relevant data can be found in the latest EU safety datasheet.

沪公网安备31011702005477号

沪公网安备31011702005477号