Product Characteristics

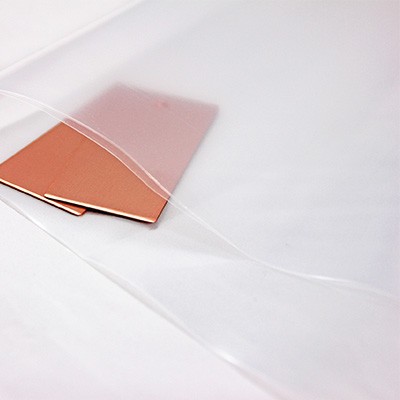

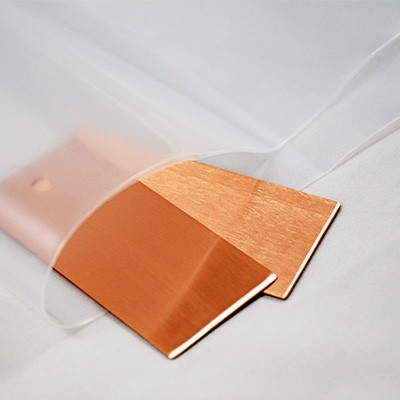

BRANOfol Cu is a special polyethylene Mono- or Coex- VCI corrosion protection film which effectively protects copper and its alloys from corrosion

during transport or storage.

It is water-proof, weldable and suitable for automatic packaging as well as bag production. BRANOfol Cu is available in different colours, from 40 to 300 μm and also as VCI-embossing film.

BRANOfol products continuously release small amounts of corrosion protection agents (VCI: Volatile Corrosion Inhibitors), helping to provide effective protection against corrosion for metal parts during transport or storage.

The protecting atmosphere is, depending on the volume of the package, available after a short time. This holds true even after having opened the package for a short time – the protecting atmosphere will be rebuilt immediately afterwards.

Duration of Protection

Depending on climate conditions and how well the packaging is sealed, BRANOfol Cu can offer protection for up to twelve months. The duration of protection can be extended if the application, storage and transport are well known.

BRANOfol Cu(nitrite free,surpass test standard DIN EN ISO 6270-2)

Protects copper and its alloys.

※ The scope of protection can be extended if the used materials and alloys are known in detail.

Advantages

· Environmentally friendly corrosion protection without oiling and greasing

· Packaging material and corrosion protection in one

· Metal parts are ready for use immediatly

· Time efficent packaging process

· Easy to dispose and recyclable

· Protects against humidity

· Non-hazardous material

· High elasticity and tear strength

· Development of customized solutions possible

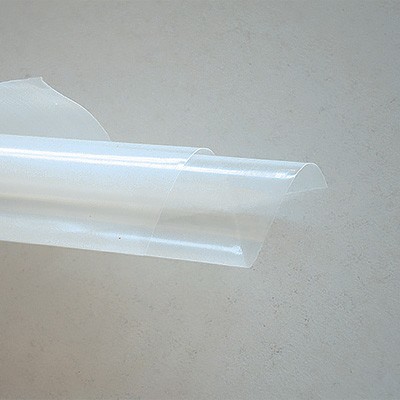

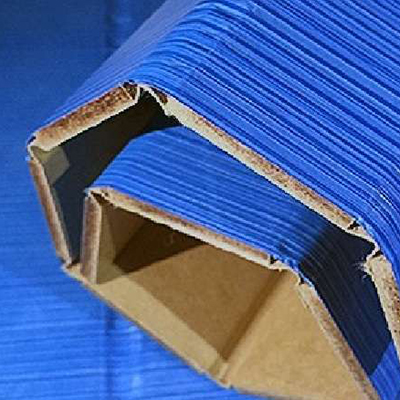

Delivery forms

Flat film, sheets, bags, half tubes, hoods, tubes, side-pleaded tubes, pallet liners, boxed hoods, elastic string bags, zip lock bags.

Storage

Cool and dry, protected from direct sunlight. Shelf-life in the original packaging up to three years.

Disposal

BRANOfol Cu can be recycled. Soiled film has to be disposed through waste incineration.

Operation safety

BRANOfol products correspond to TRGS 615. For further information please see the safety information sheet.

Types

Additional to the standard, BRANOfol Cu is expandable with different additives or polymers for shrinkable, high tear-proof, UV-stable and flame-retardant properties.

Facts

| Parameter | Test method | Unit | BRANOfol |

Tensile strength lengthwise/transversely | DIN EN ISO 527- 3/2/500 | MPa | > 14 |

Stretching lengthwise/transversely | DIN EN ISO 527- 3/2/500 | % | > 250 |

| Water vapour permeability | DIN EN ISO 5106 (23 °C, 85 % r. F.) | g/m2 * d | ≤ 1 |

| Operating temperature | Temporary: max. 70 °C Constantly: -10 °C bis 40 °C | ||

| The mechanic parameters surpass the specifications of the norm DIN 55530. | |||

The information corresponds with typical values of BRANOfol 100μm VCI film Binding are the respective product specifications.

Please pay close attention to thickness and impermeability to water vapour when selecting your VCI films. Both of these parameters are of decisive importance for corrosion protection and should therefore be selected with the specific application in mind.

All of the information contained herein is based on current knowledge and is not binding. Modificationmay be necessary to suit conditions at the location of use. No claims for damages can be made in this regard.

沪公网安备31011702005477号

沪公网安备31011702005477号