Neutral Cleaning After Thermal Deburring (TEM) and Electrochemical Machining (ECM)

Are you looking for an eco-friendly and gentle method to remove oxide layers? Great! DST-DEBURR is our popular pH-neutral, water-based metal cleaner designed for neutral cleaning after thermal deburring (TEM) and electrochemical machining (ECM), effectively removing oxide layers.

Avoid letting today’s cleaning methods create pollution risks tomorrow. Here are 3 reasons to choose the DST-DEBURR industrial cleaning solution:

01

Prevent Hydrogen Embrittlement

No more worries about part breakage or cracking. The DST-DEBURR series does not introduce hydrogen to surfaces during cleaning, eliminating hydrogen embrittlement.

02

Improve the Working Environment

The water-based DST-DEBURR series, combined with ultrasonic technology, replaces acidic pickling tanks. Effluent treatment is simplified: no dilution or neutralization required.

03

Optimize Production Processes

Parts emerge clean and ready for use—no manual or additional cleaning needed. This frees up time for actual production.

Customer Case

DANFOSS POWER SOLUTION

✦

✦

✦

Manufacturing Industry

Sustainable Solutions with Higher Quality

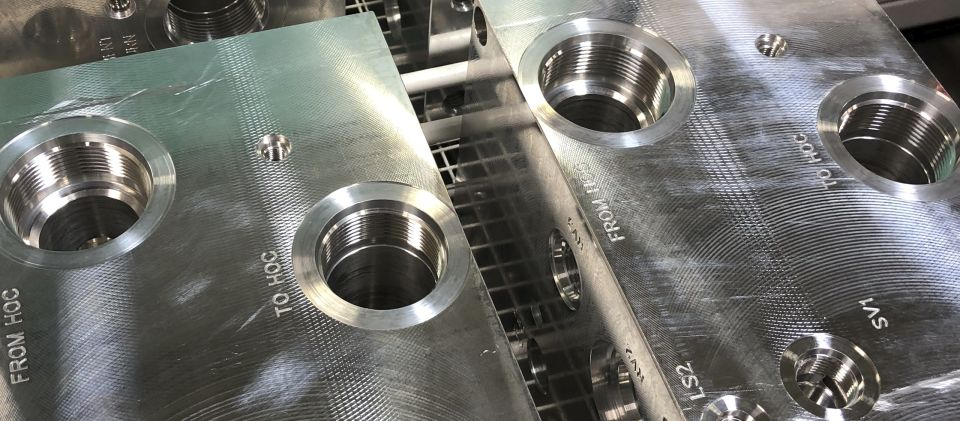

Danfoss Easley, located in South Carolina, USA, supplies mobile hydraulic systems for agricultural machinery and off-highway vehicles (OHV). As a supplier, delivering high-quality hydraulic components is critical to ensure efficient and failure-free operation for customers.

Danfoss Easley faced challenges with oxide removal after thermal deburring (TEM) and was dissatisfied with the quality of cleaned hydraulic manifolds. DST-DEBURR accepted the challenge.

Optimized Cleaning Process, Enhanced Quality

Danfoss Easley previously used oxide removal tanks to clean hydraulic components. However, daily issues led to a tank lifespan of just one week, with poor cleaning results and residual oxides on parts.

The process consumed significant resources: water, time, and energy (heated to 70°C). Post-cleaning, parts required cooling channels before further processing. This repetitive weekly process wasted time, energy, water, and chemicals.

Reduced Chemical and Water Usage at Lower Temperatures

Our goal was to reduce water and chemical consumption for Danfoss Easley while improving cleaning quality. Here’s how we succeeded:

By adopting DST-DEBURR, Danfoss Easley lowered water temperature to 45°C and extended tank solution replacement from weekly to monthly. Eliminating the need for cooling channels post-cleaning streamlined workflows.

Hydraulic manifolds are now immediately ready for further processing, enhancing efficiency.

Sustainable Solutions Without Compromising Quality

Lowering tank temperatures and reducing chemical usage benefits the environment. This sustainable approach optimized Danfoss Easley’s hydraulic manifold processing, saving time and costs while delivering higher-quality products.

|

Key Results |

|

|

1 |

Temperature reduced from 70°C to 45°C |

|

2 |

~50% savings in energy and carbon emissions |

|

3 |

Higher post-TEM quality |

|

4 |

Biodegradable solution—smaller carbon footprint |

|

5 |

Stable processes—more efficient workflows |

These impressive results make DST-DEBURR the smart choice.

沪公网安备31011702005477号

沪公网安备31011702005477号